NCAT – Non Contact BFR Tester

ANV Laser is proud to introduce the NCAT (Non-Contact Af Tester) – a novel Bend and Free Recovery (BFR) testing device that can determine the Start and Finish Af (martensite-to-austenite transformation) temperatures for each of several devices, of different shapes at the same time.

NCAT Customers

Companies that purchased and use our NCAT BFR testing device:

Typical BFR Test Protocol

The test specimen is:

- Cooled to its nominally fully martensitic phase.

- Deformed, by bending.

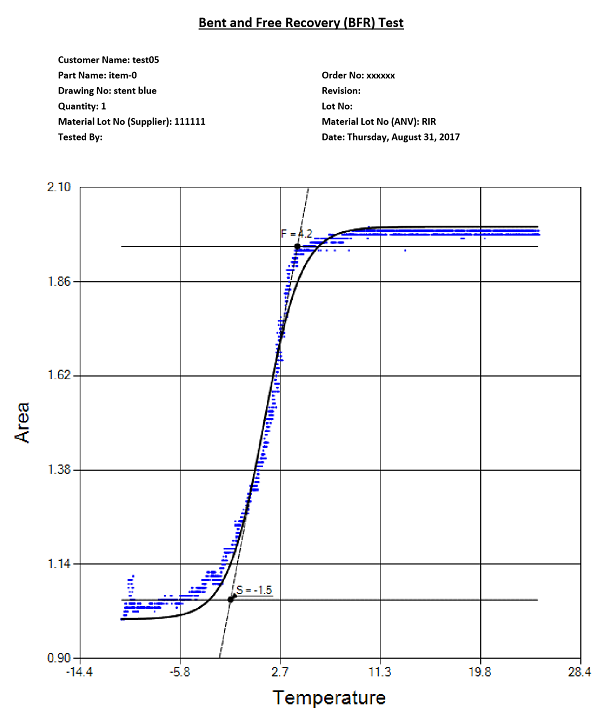

- Heated to its fully austenitic phase while the motion (recovery) of the specimen is measured and plotted against the temperature.

How NCAT Works

The NCAT’s proprietary image processing software automatically detects the boundary of each of the fully annealed or heat-treated nickel titanium items, placed in the chilled test tray. In the user-friendly graphic interface, the tester easily deletes any non-item artefacts that were detected, and then chooses – per object the area detection method for the test, such as object boundary, inscribed or described circle, parallel lines, described rectangle, convex hull.

The tester then defines, for each object, the minimum and maximum boundaries for AREA (to be plotted on the Y axis) and TEMP (to be plotted on the X axis). The tester can also determine the rate of heating that will be generated by the NCAT’s unique heating mechanism. When satisfied with all parameters, the tester initiates the test and an AREA/TEMP graph is plotted for each object.

When the temperature reaches the user-defined end-temp, the test stops automatically. The test plot for each tested item can be saved as a report that shows its AREA/TEMP graph and the calculated StartAF and Finish AF temperatures.

NCAT Benefits:

- Volume testing, suitable for production: For the first time multiple, different-shaped parts can be tested simultaneously in the same tray.

- Testing of very small parts: For the first time BFR testing can be carried out on parts that weigh less than 3 grams.

- More cost-effective and more accurate than traditional BFR testing.

- Flexibility: All test parameters can be adjusted per item, and parameter settings saved in a recipe that is easily retrieved the next time the same item is tested.

- Customizable: The NCAT can be customized to fit a customer’s unique QA requirements.

Key NCAT Features:

- Full control over experiment, camera, and image processing parameters: number of frames/buffer, contrast/brightness, end-temp, etc.

- Wide range of object area detection methods: boundary, parallel lines, inscribed/described circle, etc.

- Plot boundaries (min/max AREA, min/max TEMP) can be adjusted separately for each object.

- Full control over rate of heating, and the test stops automatically when it reaches the user-defined end-temp.

- Each item’s graph and Start and Finish AF temperatures can be saved as a report.

NCAT Specification:

What’s Included

- Digital Camera: A camera mounted on a stand that allows the tweaking the camera distance from the measuring scene.

- Lenses: Lenses allow making manual focus and aperture settings.

- Light system: Light system that shell highlight the scene with diffused light. No reflections and glares are allowed.

- Beaker

- Non-Contact Temperature sensor: Range of measurement temperatures from -50° C up to 100° C.

- Heater

- Enclosure

- PCAT ver. 1.4.00 Software allowed following:

- Test and document Af temperatures for each of several devices, of different shapes, at the same time.

- All test parameters can be adjusted per item, and parameter settings saved in a recipe that is easily retrieved the next time the same item is tested.

- Testing of very small parts.

- Volume testing, suitable for production: For the first time multiple, different-shaped parts can be tested simultaneously in the same tray.

- Ability to change the heating rate.

- Start and Finish AF temperatures can be plotted according to:

- ASTM F2082 One Stage

- ASTM F2082 Two Stage

- ASTM F2082 Af-95%.

- Fixed Offset 5%.